Screen printing

When you think of printing on a t-shirt, you are most likely thinking of screen printing. A thin layer of finely woven material (traditionally made of silk but more commonly synthetic fibre now days) is stretched tightly across a wooden frame. The screen is coated in a light-sensitive emulsion into which the design is burned using transparent prints and UV light. Ink is then pressed through the screen onto the surface to be printed.

Although typically associated with apparel printing, screen print can be applied to a wide array of items.

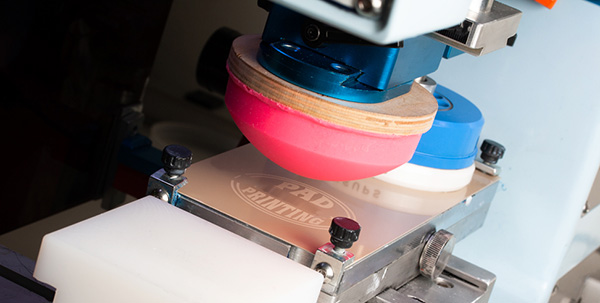

Pad printing

The ideal method for printing onto curved or uneven surfaces. The artwork is etched into a printing plate which is then coated in ink. Excess ink is removed from the printing plate leaving only the design filled. A flexible silicon pad is then used to transfer the ink from the plate to the product. The flexibility of the pad means it can wrap around curves.

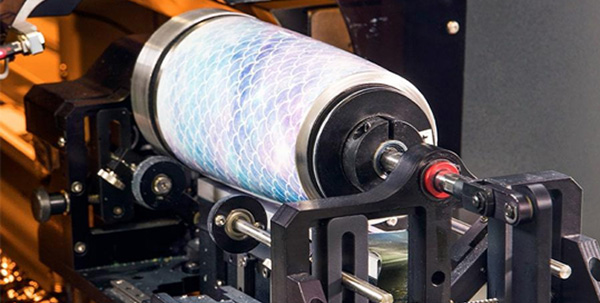

Sublimation printing

Dye sublimation printing is a digital transfer printing method widely used for textile print. Designs are printed onto a transfer medium using specialty inks. Using heat, the inks are sublimated – turned into a gas – which then embeds into the surface of the item being printed. Sublimation printing is great for full colour prints, such as photographs. As it is a digital print method it is often used for smaller print runs than other traditional printing methods where the setup costs might make it unfeasible. Sublimation printing does have some limitations, however. The material being printed needs to be synthetic, preferably polyester. Complete colour matching also cannot be guaranteed with sublimation printing.

Digital print

Similar to your inkjet printer at home, digital printers are most commonly used to print paper, vinyl and magnetic substrates. More advanced digital printers can also print directly onto certain products. Digital printing allows high-vibrancy full-colour prints on a vast array of products.

Rotary Digital Printers are designed to print cylindrical products such as water bottles. These products are held in a carrier which rotates them under the heads of the printer. This means they can be printed almost all the way around.

Some products can accept Direct Digital Print. This method prints full colour designs directly onto the product. A white base can be printed under the colour enabling bright, colourful prints on darker coloured items.

Digital transfer

Used for textiles, such as apparel and bags, full-colour designs are digitally printed onto a transfer substrate. The transfer adheres to the fabric resulting in a long lasting, flexible print. A white base is used to ensure the colours are bright and clear even on dark surfaces.

Embroidery

A traditional decoration method that has been used for centuries. Fine coloured threads are stitched through the fabric to create the design. The threads give a slightly raised finish and a higher perceived value.

Embroidery costs are based on the number of stitches. You can use our handy stitch estimator to find out how many stitches your design will need.

A couple of things to bear in mind when choosing embroidery. Due to the thickness of the threads used, the detail achievable is lower than some other decoration methods. To ensure legibility of text, the minimum height of letters should be 5mm.

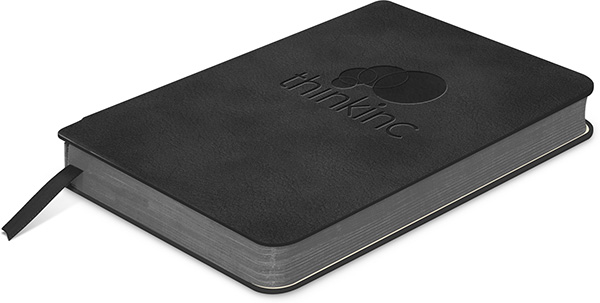

Debossing

Debossing is an elegant and understated method of decoration. A heated custom made metal stamp is pressed into the surface of the product, stamping the design into the material.

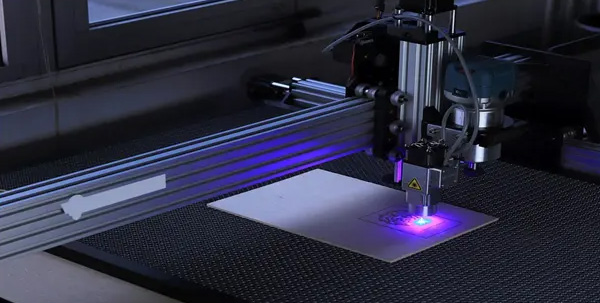

Laser engraving

Laser engraving needs little explanation. A computer controlled laser burns the design into the surface of the product and as such this decoration method is extremely durable and long lasting.

Finishes for metal products

Our metal items, such as lapel pins, medallions, and plaques, can be produced with an almost endless combination finishes.

Plating. The first stage in finishing any of our metal products is electro-plating. A range of metals are available for plating including gold, silver, brass, copper, and nickel. Once plated, the products are then polished to a high shine. Once this is done, they are good to go, or you could add further finishes.

Soft enamel. If you want a splash of colour in your products you should go for soft enamel. The colours are hand applied by injecting the enamel into the recessed areas of the item using syringes. The enamel is then cured, and a protective epoxy bubble added to the surface. Soft enamel can be used in conjunction with most of our finishing options.

Antique finish. This finish is called antique as it gives an aged look. After plating, the items are placed into a bath containing an oxidising solution which causes the surface to darken. After being washed and dried the products are given a light polish to remove the oxidisation on the raised parts of the design leaving the recesses dark. The antique finish can be applied to silver, brass, copper, nickel, and pewter plating, and is great for bringing out the details in 3D engravings.

Sand blasting. The background of the products is sand blasted to achieve a frosted finish while the raised surfaces remain brightly polished. Sand blasting provides a visual contrast between the raised design and the background and gives a dignified and classy appearance. Sand blasting is only suitable for die-struck products.

Two-tone plating. For a very special look with a higher perceived value, you can't go past two-tone plating. After being silver plated a masking agent is applied to the surfaces of the design that is to remain silver. The products are then plated with gold which only bonds to the exposed surfaces. Two-tone plating can be used in combination with soft enamel and sandblasting.